What is Digital Twin?

A digital twin blends the physical and digital worlds. The digital twin knows the current state, mimics the future state, and serves as a foundation for optimisation by recording real-time data. It allows for the early detection of problems. A digital twin is a constantly updated virtual representation — a true-to-reality simulation of physics and materials of a real-world physical asset or system. Digital twins are not limited to inanimate items and humans. They can be used as a sandbox for cyberattack simulations as a virtual depiction of computer networking architecture. They can simulate a fulfilment centre process to test human-robot interactions before activating certain robot functionalities in real-world settings. The possibilities are only limited by one's imagination.

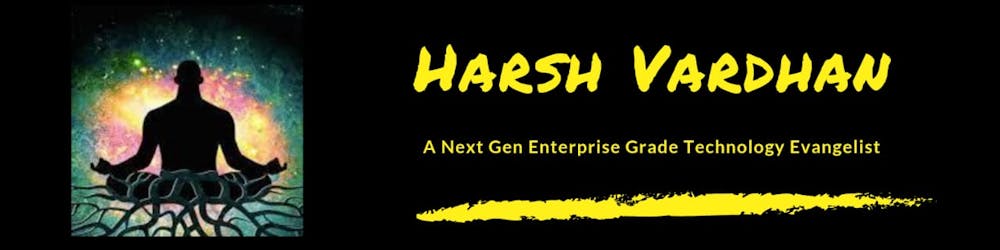

The above-shown flow/process informs and updates the current state of the physical product on the digital twin through a variety of measurements across multiple dimensions.

Digital Twin and Business Value

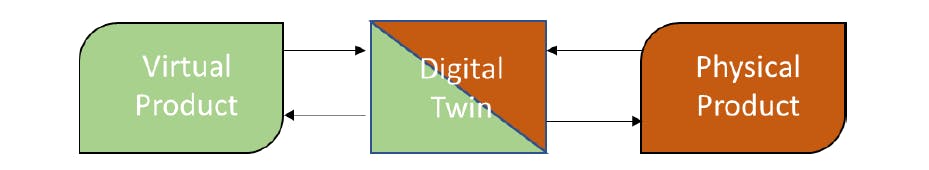

The first question that comes to mind is ‘How Digital Twins can be implemented and what business value does it provide?” To understand Digital Twins' business value, we need to first understand the economic trade-off. The complexity of a Digital Twin Implementation is directly proportional to its economic benefits. The kind of information collected also plays a significant role in the DT overall. If the information collected using the incoming data is not at its full potential, then the complexity of DT does not make sense and will not provide the expected business value. Let us understand with the below chart, the X-axis shows the cost and complexity whereas the Y-axis shows the business value. If the richness of information starts to grow, the complexity of implementation also grows with it. The data becomes contextual and makes more sense to obtain reliable insights which eventually result in increased business value.

Let us understand the three blocks using an example of an electric motor as a product.

The Green Block – Here we have the design information of the electric motor, The information is being collected as the electric motor is being manufactured. Design information refers to the data, documents, and specifications that are created and used during the process of designing a product, system, or structure. It encompasses all the information necessary to guide the development of a design, whether it is for a physical product or a software application. This stage has specifications of the product which include material details, dimensions, tolerances, and performance criteria.

The Yellow Block – This block contains the manufacturing data along with design data. Manufacturing data includes the serial number of the product, environment conditions in which the product is manufactured, the batch in which it is produced, the number of workers required, temperature of alloys at the time of moulding, parts of the electric motor etc. comes under this block.

The Red Block – This is the most expensive and informative of them all. Let us assume that the product left the manufacturing facility and is installed on the customer premises. Now the data which is collected is contextual data and it is much more valuable and insightful to deal with real-world situations and for future improvisation in the product. Errors can be recorded, and future predictions can be made. The on-premises data can be used to better the existing manufacturing process for better product building.

Elements of Digital Twin

Data: The information used to develop and maintain the digital twin is referred to as data. This information may come from sensors, actuators, or other sources.

Model: A model is a mathematical representation of a physical entity. This model is used to imitate the physical entity's behaviour.

Connectivity: It is the method that enables the digital twin to engage with the real object. This can be accomplished via sensors, actuators, or other devices.

Analytics: It is the process of gathering insights from data to construct and manage the digital twin. This data can be used to improve the physical entity's performance.

Interface: The interface is how users interact with the digital twin. This can be accomplished through a graphical user interface, a web application, or another method.

Applications

Product Design and Development: The use of digital twin technology in product design and development is an innovative strategy that can improve the efficiency and efficacy of the product development process. A digital twin is a virtual replica of a physical product or system that can be used throughout the product's lifetime.

• Ideation and conceptualization: Before creating actual prototypes, use digital twin models to simulate product ideas and concepts. This aids in determining the viability of a design and detecting potential concerns early in the development process.

• Simulation and design: Make a digital twin of the product, complete with all its components and subsystems. This virtual model can be used for thorough design and simulation, allowing engineers to assess and evaluate multiple design iterations virtually.

• Communication and collaboration: By offering a shared platform for exchanging and visualising the product's digital representation, digital twins enhance cooperation among cross-functional teams, including designers, engineers, and stakeholders.

• Testing and prototyping: Use digital twins for virtual prototyping and testing instead of several physical prototypes. This minimises the time and cost of physical prototyping.

• Monitoring and optimisation in real time: Digital twins can be used to monitor and optimise production processes during the manufacturing phase. This guarantees that the finished product meets the design criteria.

• Quality Control: Use digital twins to do virtual inspections and quality checks, minimising the risk of final product errors.

• Lifecycle Management (LCM): Extend the use of digital twins beyond product development and into operations. To guarantee that the product continues to run smoothly, use them for maintenance, performance monitoring, and predictive maintenance.

• Data Analytics: Massive volumes of data are generated by digital twins, which can be analysed for insights. This data can be used to improve product performance, quality, and efficiency using machine learning and AI algorithms.

• Customization: Mass customization is made possible by digital twins, which let producers to customise items to consumer needs while retaining manufacturing efficiency.

• Customer Service and Support: Give customers access to the digital twin of their purchased product, allowing them to monitor its performance and obtain real-time support.

Product Optimization: Product optimisation with digital twin technology is building a virtual clone of a physical product or system and using it to continually monitor, analyse, and optimise its performance, efficiency, and dependability throughout its lifecycle.

• Monitoring in Real Time: Install sensors and data gathering systems on the physical product to collect real-time data about how it works. This data is then used to continuously update and improve the digital twin.

• Performance Evaluation: Analyse the acquired data with the digital twin and evaluate the product's performance against design criteria and key performance indicators (KPIs).

• Predictive Maintenance: Anticipate and prevent equipment failures, use machine learning algorithms and predictive analytics. You may schedule maintenance or replacement of components before they fail by analysing data from the digital twin, saving downtime and repair costs.

• Energy Conservation: Optimise the product's energy consumption by analysing sensor data and adjusting its operation. This can result in significant energy savings as well as a reduction in environmental impact.

• Supply Chain Optimisation: Extend the concept of the digital twin across the whole supply chain. Monitor and optimise the movement of raw materials, components, and finished goods to eliminate delays, cut costs, and increase overall efficiency.

• Regulatory Compliance: Monitor and document essential data throughout the product's lifecycle to ensure that it continuously conforms with industry norms and standards.

• Lifecycle Analysis: Examine the product's environmental impact from raw material extraction to disposal to discover potential for sustainability improvements.

• Continuous Improvement: Drive continuous improvement initiatives with insights gathered from the digital twin. Update the product design and operation regularly to improve performance and efficiency.

• Customer Experience: Using data from the digital twin, gain a better knowledge of how customers use the product. Use this data to improve the user experience and address any issues that arise.

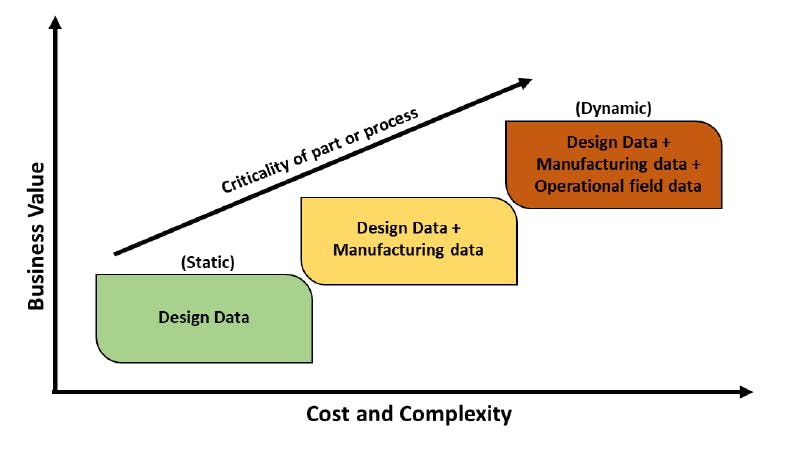

Product vs. Process Digital Twins

Digital Twin on different hyperscalers:

Take advantage of the scalability, computational power, and storage capacities of hyperscale cloud platforms, Digital twin technology can be deployed on a variety of hyperscale cloud platforms. The cloud provider you choose is heavily influenced by your specific requirements, current infrastructure, and budget constraints.

AWS provides a comprehensive range of services for developing and deploying digital twin systems or apps with twin-like characteristics. These services can be combined to form a customised digital twin solution tailored to your individual requirements. Here are several AWS services that are often used in the development of digital twin applications:

i. Elastic Compute Cloud (EC2) by Amazon: EC2 offers scalable virtual machine instances for hosting the backend services and computational resources required for digital twin simulations and data processing.

ii. Amazon Web Services IoT Core: IoT Core connects and manages IoT devices, making it ideal for capturing real-time data from physical assets in the digital twin.

iii. S3 (Simple Storage Service) by Amazon: S3 can be used to store and manage digital twin data and model files, such as 3D models, sensor data, and historical records.

iv. Lambda on AWS: You can use Lambda to run serverless code in response to events. It can be used to initiate actions or computations based on data from IoT devices or other sources.

v. Kinesis on Amazon: Kinesis offers streaming data services that allow you to ingest, process, and analyse real-time data streams created by IoT devices. It is handy for processing massive amounts of data in near real time.

vi. Sage Maker by Amazon: Sage Maker is a machine learning service that can be used to construct and deploy machine learning models within the digital twin for predictive maintenance, anomaly detection, and optimisation.

vii. Amazon API Gateway (API Gateway): API Gateway enables you to develop APIs for securely accessing and managing the functions and data of your digital twin.

viii. CloudWatch by Amazon: CloudWatch monitors and observes your digital twin application, allowing you to analyse performance, spot abnormalities, and fix problems.

ix. VPC (Virtual Private Cloud) on Amazon: VPC allows you to construct a private network for your digital twin application to provide secure and controlled resource communication.

x. Identity and Access Management (IAM) on AWS: IAM is essential for controlling access to your digital twin's resources and services, ensuring that only authorised users and apps interact with the system.

xi. Amazon Web Services IoT Analytics: IoT Analytics cleans, enriches, and analyses IoT data from multiple sources, making it acceptable for data preparation before it enters the digital twin.

Azure Digital Twins is a Microsoft Azure cloud-based platform for developing digital twin solutions. It allows you to construct full digital representations of physical settings, assets, and systems, as well as a collection of services and tools to help you develop and manage digital twin applications. The combination of the following services is required for Azure Digital Twins implementation:

i. Azure Digital Twins: The central management and deployment solution for digital twins. It offers APIs and capabilities for developing, managing, and interacting with digital twin models and instances.

ii. The Azure IoT Hub: IoT Hub securely connects and manages IoT devices and sensors, allowing you to collect data from physical assets and integrate with Azure Digital Twins.

iii. Insights into Azure Time Series: This service can store and query time-series data from sensors and devices. It can be used in conjunction with Azure Digital Twins to analyse historical data and track real-time events.

iv. Cosmos DB in Azure: Azure Cosmos DB is a globally distributed, multi-model database service for storing and querying data on digital twins. It provides scalability and low-latency data access.

v. Azure Services: Serverless event-driven programming can be accomplished with Azure Functions. You can automate operations or execute custom logic by triggering functions depending on occurrences in your digital twin environment.

vi. Stream Analytics on Azure: Stream Analytics is a real-time data processing and analytics platform. It can be used to process incoming data streams from IoT devices and make data-driven choices.

vii. Logic Apps in Azure: Logic Apps allow you to create workflows and automate business activities. They can be used to build bespoke workflows that interact with digital twin data and initiate actions.

viii. Microsoft Azure Active Directory (Azure AD): Azure AD assists in the management of authentication and access control for your digital twin application. Roles and permissions can be defined to ensure that only authorised people and services can access and alter digital twin data.

ix. Microsoft Azure Maps: Azure Maps offers geospatial and location-based services that can be used in conjunction with Azure Digital Twins to deliver location intelligence to your digital twin models.

x. Azure DevOps: Azure DevOps can be used to ensure the smooth development and deployment of your digital twin application using continuous integration and continuous deployment (CI/CD).

xi. Power BI on Azure: Power BI and Azure Digital Twins can be used together to produce interactive dashboards and reports for visualising and analysing digital twin data.

xii. Azure Security Centre and Azure Monitor: These services provide monitoring, logging, and security capabilities to assure your digital twin environment's health, performance, and security.

Google Cloud IoT Twinmaker is a fully managed service that allows you to develop, deploy, and manage digital twins. A digital twin is a virtual representation of a physical thing or system. It can be used to monitor the performance of a physical object or system, simulate alternative scenarios, and discover potential problems.

i. Core Google Cloud IoT: IoT Core connects and manages IoT devices, making it ideal for gathering real-time data from physical assets and integrating it into your digital twin.

ii. Pub/Sub on Google Cloud: A messaging service that may be used to ingest, process, and send real-time data from IoT devices and sensors to other GCP services for analysis is known as Pub/Sub.

iii. Dataflow on Google Cloud: Dataflow is a real-time data processing and analysis tool that allows you to do calculations and transformations on incoming data streams.

iv. Big Query on Google Cloud: Big Query is a sophisticated data warehouse capable of storing and analysing enormous amounts of data from digital twin sources, allowing you to obtain insights from both historical and real-time data.

v. GKE (Google Kubernetes Engine): GKE provides containerized apps with a managed Kubernetes environment. GKE can be used to deploy and manage containerized digital twin system components.

vi. Google Cloud Services: You can use Cloud Functions to run serverless code in response to events. It can be used to execute actions or compute computations based on data generated by digital twin models.

vii. Platform for Google Maps: Google Maps services can be connected to give geographic and location-based information, hence improving the location intelligence of your digital twin models.

viii. Machine Learning Engine on Google Cloud: If machine learning is a necessity for your digital twin, ML Engine may be used to design, train, and deploy machine learning models.

ix. Personalised Development: Using GCP's compute and storage capabilities, you may also create bespoke applications and services to manage digital twin models, simulations, and data integration.

Benefits of using Digital Twins

Improved efficiency: By modelling numerous situations and identifying potential problems, digital twins can be used to improve the efficiency of operations.

Reduced costs: By optimising processes and discovering areas for cost savings, digital twins can be used to reduce costs.

Increased safety: By recreating dangerous events and identifying potential hazards, digital twins can be used to improve safety.

Better decision-making: By offering insights into the behaviour of real items, digital twins can help people make better decisions.

New product development: By modelling the performance of diverse designs, digital twins can be used to develop new products and services.

Personalised services and recommendations: Digital twins can be used to improve the customer experience by delivering personalised services and recommendations.

Improved asset management: By monitoring asset performance and spotting concerns, digital twins can be used to improve asset management.

Supply chain optimisation: By tracking the movement of goods and commodities, digital twins can be used to optimise the supply chain.

Reduced environmental impact: By optimising energy usage and trash disposal, digital twins can be used to lessen the environmental impact of operations.

Challenges

The technology is now facing common issues with AI and IoT technologies. Data standardisation, data management, and data security are among them.

Other issues include the need to upgrade existing IT infrastructure, connectivity, privacy, and security of sensitive data, and the lack of a standardised modelling technique.

The excessive cost of implementation, rising demand for power and storage, integration issues with existing systems or proprietary software, and complexity of its architecture are all expected to stymie the Digital Twin market's growth.

Implementing Digital Twins solutions is expensive, including substantial investments in technological platforms (sensors, software), infrastructure creation, maintenance, data quality control, and security.

Future

Soon we can expect Digital Twins to proactively search for data, harvest data, and request that sensors capture certain types of data with customized sensitivity.

In addition, as they become smarter, we can expect Digital Twins to develop their own model of the world, in other words, to become increasingly aware of their environment.

As another major step forward, we can expect them to interact with other Digital Twins and with their Physical Twin at a semantic level, thus getting rid of the need to have predefined syntax (standards) for enabling communications.

Furthermore, we can expect them to become capable of playing the role of proxy in cyberspace and, through actuators, in the physical space.

Additionally, they will be able to replicate themselves in several instances, as a need arises, creating instances that can act in parallel.

Finally, we can expect Digital Twins to learn from their environment and experiences and be able to self-assess the quality of the lessons learned.

Conclusion

Digital twin is a game-changing technology paradigm with the potential to disrupt industries and redefine how we interact with the real world. These virtual copies, which are powered by real-time data and advanced analytics, provide several benefits across a wide range of industries, from manufacturing and healthcare to energy and urban planning. Organisations can use digital twins to make data-driven decisions, optimise performance, and increase efficiency. They shorten product development processes, minimise downtime, and lower maintenance costs. They avoid breakdowns before they occur with predictive maintenance capabilities, ensuring that assets run at peak performance.

Digital twins will continue to evolve and revolutionise sectors as we move farther into the digital age. Their capabilities are only limited by our imagination and the amount of data we can collect and analyse. Currently, embracing digital twins is not an option; it is a requirement for being competitive, efficient, and responsive to our world's ever-changing expectations. Digital twins are more than just tools; they are the link between the physical and digital worlds, and their impact on our future is enormous.

References:

https://xmpro.com/microsoft-azure-digital-twins-everything-you-need-to-know/

https://docs.aws.amazon.com/iot-twinmaker/latest/guide/what-is-twinmaker.html

https://slcontrols.com/en/what-is-digital-twin-technology-and-how-can-it-benefit-manufacturing/

https://digitalreality.ieee.org/images/files/pdf/Future_Digital_Twins-FINAL2.pdf